What We Will Be Covering

- Alternate Drive Mechanisms

- Providing assist for self-propulsion of a manual wheelchair

- Lever drives

- Arm-crank drives

- Geared hubs

- Reverse pushrim drives

- Push rim-activated power assist drives

We are going to be focusing on power add on options as well as a few other options to help optimize self-propulsion for people who are using manual wheelchairs. This is a really exciting cutting-edge area it is helpful to you and to the clients whom you serve. We are going to talk about a category of seating and mobility equipment called alternative or alternate drive mechanisms. This is not a very consistent term. You might hear a lot of different terminology around this area, but this is the term that is utilized in our latest text on seating and wheeled mobility. We are going to talk about how these alternate drive mechanisms provide assistance for self-propulsion of a manual chair using either a lever drive, an arm-crank drive, geared hubs, a reverse pushrim drive, or those PAPAWs, push rim-activated power assist drives.

SMS Series

- This is part of a series of webinars designed to prepare the participant for the Seating and Mobility Specialist examination

- And… develop more advanced seating and wheeled mobility skills

The Seating and Mobility Specialist certification is offered through RESNA. They have two certifications, the ATP, or Assistive Technology Professional, as well as the SMS or Seating and Mobility Specialist. If you are pursuing your Seating and Mobility Specialist certification, you have to already have received your ATP. We do have a series of courses on occupationaltherapy.com designed to prepare you for that particular certification, and again this series is designed to provide more advanced information in preparation for the SMS. But, regardless of whether you are interested in one of those certifications, I really hope this does help you develop more advanced seating and wheeled mobility skills because that helps any of us do our job even better.

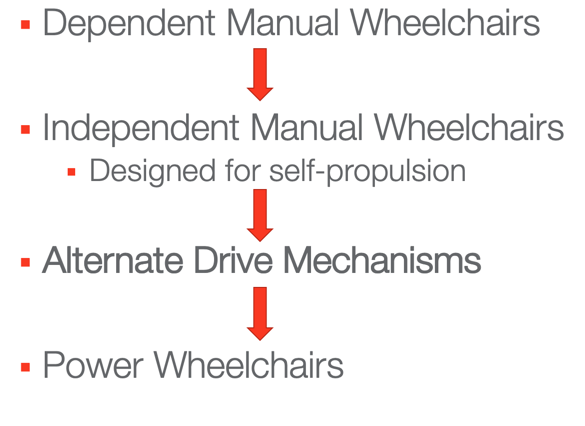

Mobility Hierarchy

There is a mobility hierarchy as seen in Figure 1.

Figure 1. Mobility hierarchy.

Depending on the client, we may start with a more dependent manual wheelchair, something that a caregiver pushes for the client. The client is unable to move on their own. From there, we try to determine if a client can be independent with a manual chair and propel it on their own. One of the courses in this series talks about ultralight manual wheelchairs which are specifically designed to optimize self-propulsion. We also have alternate drive mechanisms. These are designed to improve the efficiency of a manual wheelchair for self-propulsion. Finally, we have power wheelchair options for someone who cannot use any of the other options in order to achieve independent mobility.

Alternative Drive Mechanisms

- Goal:

- Improved mechanical efficiency

- Maintain the transportability, versatility, and aesthetics of a manual wheelchair

(DiGiovine & Berner, 2018)

Our goal with these options is to improve the mechanical efficiency of the system. Manual wheelchairs have been around for quite a while now, but they have not really changed that much. If we look at really early models, the seating and wheel position may have changed, but the overall design has remained the same. The seated person grasps a wheel and pushes it forward to make the wheelchair move. We have had design changes like demonstrated in the ultralights to optimize that propulsion but some of the strategies we're going to talk about today are an attempt to change the efficiency of how this wheelchair works. Can we give this a mechanical advantage so the user has to exert less effort, and again as a result is more efficient in their propulsion?

Figure 2. Example of an alternative drive mechanism (NuDrive Air).

With this option, we can maintain the ability of the client or caregivers to transport this device. It gives a little more flexibility to the user. Additionally, many people are going to prefer the aesthetics of their manual chair as opposed to a power wheelchair.

Who Is This Appropriate For?

- It is well documented that people who self-propel a manual wheelchair, even an appropriately configured ultralightweight manual wheelchair (MWC), are prone to:

- Repetitive stress injuries

- Shoulders, wrists

- Pain

- Repetitive stress injuries

- This can worsen to the point that mobility is compromised.

It is well documented that people who self-propel a manual wheelchair, even if we have set it up as well as we can, that people who self-propel are prone to pain and repetitive stress injuries, particularly of the shoulders and wrists.

Figure 3. Example of an ultralight wheelchair (Quickie Q7).

We are all aging including people with a disability. This is really becoming a problem. Many years ago, if someone sustained a spinal cord injury, for example, their average lifespan was only six years. Now people who have sustained a spinal cord injury may live close to a typical lifespan, and this person may be propelling for decades. It is very important that we keep this in mind that even if this person is doing just fine with their self-propulsion right now. They are at high risk of these repetitive stress injuries and pain, and this can worsen to a point where this person can no longer use their manual chair at all. If there are some things we can do preventatively so this person can stay with manual mobility as long as possible, then that is part of our job. Who could benefit from these alternative options?

- A person who can self-propel, but:

- Has upper extremity injury and/or pain

- Has decreased cardiopulmonary function

- Has decreased strength and endurance

- Is less efficient in mobility secondary to aging with a disability or aging in general

- Is a long-term MWC user who may have lost efficiency

- Is an MWC user who cannot manage slopes, varied terrain and/or long-distances without assistance

These additional options to increase the efficiency of a chair are designed for a person who can self-propel but perhaps has upper extremity injury and/or pain or is at high risk for that. It might be a little harder to convince someone who is successful and not experiencing injury or pain right now to consider these options. It may also be difficult to convince a funding source to consider these options unless there is already an existing issue. But, if this person has an upper extremity injury, pain, or decreased cardiopulmonary function, this could be a great justification for this equipment. They may say, "I can only push so far so long with so much effort before it just takes too much of a cardiovascular toll on my body. Or, "My heart and breathing rates raise up too high." This person may simply have decreased strength and endurance. A person who is less efficient in mobility secondary to aging with a disability or aging, in general, would be another category. They do not have the same strength and endurance. Some of our clients may have been very efficient with their mobility in the past, but they are now getting older and aging with a disability. They are not doing as good a job as they used to in terms of overall time, distance, and effort. It might be a manual wheelchair user who does fairly well over smooth level surfaces but is now having difficulty with slopes, varied terrain, and/or long distances without help. And perhaps, this person is propelling through the community and accessing ramps. They might have difficulty with having enough strength to get up a ramp and preventing themselves from rolling back down. They also might have difficulty slowing themselves so they do not go barreling down the ramp when they exit the building. Longer distances or bumpy roads can be too challenging as well.

Non-powered Options

- Geared systems

- Lever systems

- Arm-crank systems

We have several different non-powered options, as much as the title of our course today is power add on, we are talking in general about alternate drive mechanisms and that includes non-powered and powered options. Let's start with these, and this includes geared systems, lever systems, and arm-crank systems.

Geared Systems

- Gear system between the handrim and the wheel

- Geared hubs

- Reverse pushrim drives

A gear system sits between the handrim and the wheel, and consists of either a geared hub or something called a reverse pushrim drive. Figure 4 shows an example of IntelliWheels.

Figure 4. IntelliWheels Easy Push.

It is called Easy Push because the gear system helps with self-propulsion and increases the efficiency of it.

- How does it work?

- Standard MWC handrim has a 1:1 ratio

- 1 push = set distance of movement

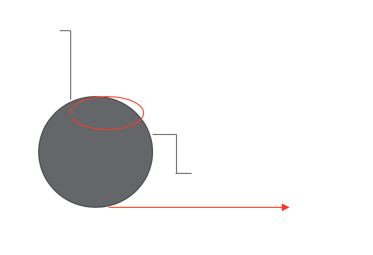

A standard manual wheelchair handrim has a 1:1 ratio. If I push on my wheel, I am going to go a set amount of distance for each push (Figure 5).

Figure 5. Example of the 1:1 ratio of movement with a standard manual wheelchair.

I give one push, my wheel goes a certain distance. Of course, it is going to depend on the slope and the terrain of how far I might go. However, typically, we have this 1:1 ratio.

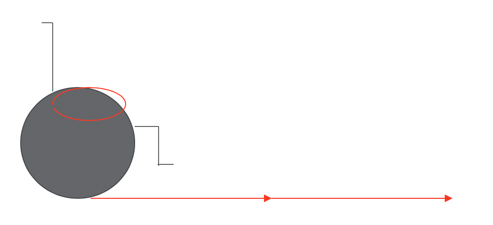

- Geared systems

- Typically 1:1 ratio for standard propulsion

- 1:2 ratio for propulsion on inclines or high rolling resistance surfaces

- i.e. carpet

- Reduces UE effort on all ramps

- Reduces abdominal activity on steep ramps

With a geared system, we have a 1:2 ratio for propulsion on inclines or on something called high rolling resistance surfaces such as carpet.

Figure 6. Example of the 1:2 ratio of movement with a geared system.

If you have never had a chance to try to propel a manual chair, I would encourage you to do so. If you are pushing on nice smooth linoleum, it is really not too difficult, but if you move over to a different type of surface such as plush carpet, it is much more difficult to push. It increases more resistance to the wheels as they attempt to roll or rolling resistance. Now, when I give one push on the wheel, I go twice the distance on those surfaces. It reduces the amount of upper-extremity effort that is required to get up a ramp. It also reduces the abdominal activity on steep ramps. Imagine sitting in a manual chair and you are trying to get up a steep ramp, not only are you putting in a lot of upper-extremity effort but also core muscles. This may not be possible for some of our clients to execute.

- Who is this appropriate for?

- Users who could not traverse certain environments without this system

- Users with reduced UE strength

A geared system can be helpful for users who could not otherwise traverse certain environments without this system. Maybe, they cannot manage those slopes or varied terrain. This is also good for users with reduced upper-extremity strength because they are going to get twice as much distance out of their effort as they otherwise would.

- Reverse propulsion

- Pulling back on the wheel moves the MWC forward

Another option is reverse propulsion where pulling back on the wheel actually moves the manual wheelchair forward. This is the reverse of how we typically use a wheelchair. Figure 7 shows RoWheels.

Figure 7. RoWheels Revolution.

The motion is similar to rowing.

- Pulling action uses muscles in your upper back and shoulders

- Larger muscles

- Encourages better posture

- Reduced risk of shoulder-related injuries

- Minimizes impact on handrim

This pulling action uses a different set of muscles than if we are pushing on the wheel. These muscles involved in our upper back and shoulders. These are larger muscles than some of the muscles we use when we are pushing forward in a standard fashion. By pulling back, it encourages a better posture because as we are encouraging trunk extension and scapular retraction as opposed to pushing the scapulas forward and more rounding the shoulders with regular propulsion. It also reduces the risk of shoulder-related injuries because of the pattern that the client is using, and it minimizes the impact on the handrim. This is a big deal. Additionally, when people push a wheelchair forward, the way their hand collides with the handrim can create a great deal of force through the wrist. And, this can lead to some of those repetitive stress injuries again. So, this is a very unique option, although not too many people use it. Many of these options are a lot easier to understand if you have a chance to hop in and try them. Again, I would encourage you to work with your local supplier or manufacturers to demo some of this equipment.

- The user must recognize the need to change gears

- Adds weight

- Most weight is by the hub, less impact on propulsion

- Minimizes roll-back on slopes

- Reduces force required to brake when going downhill

For geared systems, the user needs to recognize the need to change gears. Geared systems also add weight. Now, most of the weight is by the hub on the axle of the wheel and that means there is less impact on propulsion than if the weight was in the front or back of the chair. It is in a good spot in terms of the center of gravity, and it can help to prevent people from rolling back on slopes. If I am trying to push up a ramp and my hand slips on that wheel or I get too tired, I might begin to roll back. These geared systems will often only allow movement forward if I am not pulling back. This means that all the effort goes into moving up the slope. This also reduces the amount of force required to brake when going downhill. Geared systems, in general, can work similarly to a bicycle. When I was a little kid, I had a bike that did not have gears. I had to turn my feet on those little pedals to turn the wheel. One turn of the pedal was one turn of the wheel. As I got older, I got bikes that had different speeds. Having gears means that depending on the gear, one turn of the pedal could result in multiple turns of the wheel. It makes us more efficient and helps us deal with certain terrain. I am going to change what gear I am in if I am going up a hill or going downhill. We can do the same thing with a wheelchair including those reverse system options. We also have a different set of muscles we are using which improves the amount of strength we can put into the task. We are also using larger muscles which improves posture and reduces a tendency towards injury. So, there are two very different options with these geared systems.

Lever Systems

- Lever arm increases torque compared with traditional handrim

- Typically levers are placed between frame and wheel

- Does not add very much to the width of the chair

- Gears may also be built-in

- The handle is easier to grasp than the handrim